IQC - The ISO Pros

of Roswell, NM & ISO 9001 Experts

Understanding what the Automotive Quality Core Tools are is one of the most effective ways on how you can promote and observe excellence in the automotive industry without spending too much money on investments.

In case you’re not aware, these Automotive Core Tools have proven their effectiveness and efficiency in the industry, becoming the key to some of the most famous Automotive manufacturers’ problems and concerns.

Deeper Look at the Automotive Core Tools

Before we get to that, it is imperative and important for us to know and what these Automotive Core Tools are for – and it’s merely a set or a group of tools used in order for companies, institutions, and businesses in the Automotive Industry to ensure that all their products and services are up to the standard and optimum.

Now, let’s get into the deeper part of what these Automotive Core Tools are:

Advanced Quality Product Planning (APQP)

In its simplest terms, the APQP is the methodology that helps in identifying the process of how a new product or service will enter the arsenal of a company. This helps in minimizing risks involved such as waste of resources, slower time to market, etc.

Failure Mode and Effects Analysis (FMEA)

Following the APQP, the FMEA is the kind of method that indulges in risk assessment and utilizes a structured approach in identifying failures in a business process or operation’s design, execution, service, etc.

Measurement System Analysis (MSA)

From its term alone, you would already know that the MSA is a tool or a methodology that is a part of the Automotive Core Tools that ensures that the organization or the company’s capabilities and competencies are relevant – and it’s measured and observed through statistical data.

Product Part Approval Process (PPAP)

The PPAP is the systematized method that enables your customer that you are capable of providing and producing parts and components in a regular and ongoing manner.

Statistical Process Control (SPC)

Last but definitely not the least is the SPC – and this is a set of tools that are used to observe, monitor, and control the overall manufacturing process; and it can be used not only by manufacturers, but by distributors, assembly facilities, and production facilities, too.

In case you want to know more about what these Automotive Core Tools are, or if you are in dire need of a company or an organization that you know can help you integrate and implement these core tools, you can bank and trust us here at IQC – the ISO Professionals.

Across the whole city of Roswell, we’ve been tagged and considered by many automotive companies as their main option in the provision of the most useful, relevant, and essential training sessions and certifications.

Wherever you are, IQC – the ISO Professionals is always open to accommodate your needs and your concerns. You can talk to us via email or via our hotline. Never worry about how or where you can get help with the Automotive Core Tools ever again!

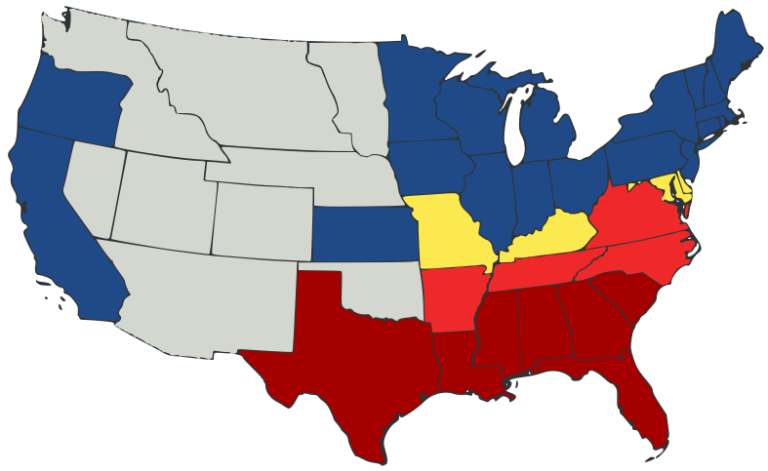

We service multiple cities throughout the state of New Mexico. We provide all the services listed below and more in every city.

If you don’t see your city listed, don’t worry. Just contact us by giving us a call or filling out the form, and we’ll dive deep to discover what are the best solutions for you and your business. See our areas of service:

With IQC – the ISO Professionals, you’ll get all of the information and the proper training that you need to go on with the industry you are in! Here are the ISO Standards we can help you with:

- Asset Management ISO 55001

- Automotive Core Tools

- Automotive IATF 16949

- Body Armor BA 9000

- Capability Maturity Model Integration

- CMMC

- Counterfeits AS6081

- Energy ISO 50001 and SEP

- Environmental ISO 14001

- Ethical Sourcing SQFI

- Facility Management ISO 41001

- Food Safety Modernization Act FDA FSMA

- Food Safety ISO 22000

- Forestry SFI ATFS

- Gluten-Free Certification

- Info Security ISO/IEC 27001

- International Traffic in Arms Regulations, ITAR

- IT Service ISO/IEC 20000-1

- Laboratory Accreditation ISO 17025

- Medical Devices ISO 13485

- Occupational Health and Safety Management System

- Packaging ISO 15378

- Quality ISO 9001

- Responsible Care RC14001

- Supply Chain ISO 28000

- Telecommunications TL 9000